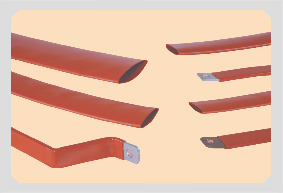

SwitchgearMV Heat Shrink Sleeve

Bus Tube is heat shrinkable tube designed to insulate busbar systems up to 24 KV & to protect against accidental flashover.

| Size | As Supplied | After Recovery | T (±10% ) | Reel length | Rectangular Bars (W+B) | Round Bar Ø | ||

|---|---|---|---|---|---|---|---|---|

| MM (min.) | MM (max.) | MM | Meters | Min | Max | Min | Max | |

| NMB 16/6 | 16 | 6 | 2 | 25 | 12 | 18 | 6.5 | 12 |

| NMB 25/8 | 25 | 8 | 2.5 | 25 | 16 | 30 | 9 | 20 |

| NMB 30/12 | 30 | 12 | 2.5 | 25 | 22 | 38 | 13.5 | 25 |

| NMB 40/16 | 40 | 16 | 2.5 | 25 | 29 | 50 | 18 | 32 |

| NMB 50/20 | 50 | 20 | 2.5 | 25 | 36 | 63 | 22 | 40 |

| NMB 65/25 | 65 | 25 | 2.7 | 25 | 46 | 82 | 28 | 52 |

| NMB 75/28 | 75 | 28 | 3 | 25 | 55 | 94 | 33 | 60 |

| NMB 85/32 | 85 | 32 | 3 | 25 | 58 | 107 | 37 | 68 |

| NMB 100/38 | 100 | 38 | 3 | 25 | 70 | 126 | 44 | 80 |

| NMB 120/45 | 120 | 45 | 3 | 15 | 90 | 150 | 55 | 96 |

| NMB 150/60 | 150 | 60 | 3 | 15 | 110 | 200 | 70 | 127 |

| NMB 180/70 | 180 | 70 | 3 | 15 | 125 | 226 | 80 | 144 |

| NMB 205/85 | 205 | 85 | 3 | 15 | 200 | 257 | 127 | 164 |

| NMB 250/120 | 250 | 120 | 3 | 15 | 220 | 314 | 140 | 200 |

| Test Description | Recorded Value | Test Method |

|---|---|---|

| Physical | ||

| Tensile Strength | 12 N/mm2 (MPA)(min.) | ASTM D638 |

| Ultimate Elongation | 300% (Min.) | ASTM D638 |

| Water Absorption | 0.5 % (max.) | ASTM D570 |

| Density | 1.20 ± 0.2 gm/cm3 | ASTM D792 |

| Hardness | 45 ? 10 Shore D | ASTM D2240 |

| Thermal | ||

| Accelerated Ageing | (120oC for 500 Hrs) | ASTM D2671 |

| Tensile Strength | 10 N/mm2 (Mpa) (min.) | ASTM D 638 |

| Ultimate Elongation | 250%(Min.) | ASTM D638 |

| Low temperature Flexibility (-40oC for 4 Hrs.) | No Cracking | ASTM D2671 |

| Heat Shock (250oC for 30 Min.) | No Cracking or flowing | ESI 09-11 |

| Shrink Temperature | 125oC | IEC 216 |

| Continuous Temperature limit | -40oC to + 110oC | IEC 216 |

| Electrical | ||

| Dielectric Strength | 22 KV/mm. (Min.) | ASTM D149 |

| Volume Resistivity | 1 x 1014 Ohm.cm(min.) | ASTM D257 |

| Dielectric Constant | 5 (Max.) | ASTM D150 |

| Resistant to track & erosion | No Tracking, erosion or flame failure upto 3.25 KV for 20 min. | ASTM D2303 |

| CLEARANCES WITH INSULATION | |||||

|---|---|---|---|---|---|

| Voltage | Medium wall Tube (NMB) | Heavy Wall Tube (NHB) | UN-Insulated Bus bars | ||

| Ph. To Ph. | Ph. to gr. | Ph. To Ph. | Ph. to gr. | ||

| 12KV | 65 | 75 | 35 | 45 | 120 |

| 17.5 KV | 85 | 105 | 55 | 65 | 160 |

| 24 KV | 115 | 150 | 70 | 100 | 220 |

| 36 KV | 200 | 285 | 140 | 190 | 320 |

- Reduce Busbar clearance.

- Prevent Busbar from chemical corrosion effected by strong acid, alkali, salt etc.

- Solve the problem of insulation among Busbar in Bus Duct.

- Halogen free, flame retardant.

- High dielectric strength.

- Highly Flexible for use on straight or angled bars without creasing.